In today’s business environments, your customers expect you to grow and keep up with their expectations. Your organization is not only compared to your competitors, but you’re also compared to the levels of customer experience from various industries. Because of this, continuous improvement in your operations is more important than ever.

Operations and Continuous Improvement

Blending operations, strategy, and continuous improvement leads to increased customer value.

Continuous + Strategic improvements

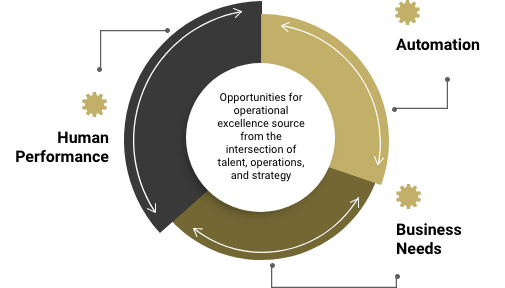

While traditionally thought of as complex plans and blueprints to make manufacturing more efficient, Continuous Improvement (CI) is more than just a single operational tool for achieving that desired result. In today’s business environment, CI ranges from creating flexible strategic plans that self-improve over time and refining business architectures to developing state of the art processes through human performance and automation—all guided by the business needs as identified in the corporate strategy.

Modern value creation that incorporates automation, machine learning, predictive analytics, and a variety of AI, robotic, and operational tools are the advances brought by this Fourth Industrial Revolution (4IR) and represent a new level of performance for the industrial value chain. Every aspect of business, from service to healthcare to sales, have a stake in Industry 4.0.

YOUR DELIVERY VS CUSTOMER NEEDS

Given the pace and pervasiveness of change, continuous improvement is key for an organization seeking to progress and develop advantages today and tomorrow.

Auditing workflows in your organization using CI tools such as Kaizen, a lean tool that promotes continuous improvement in quality, technology, processes, productivity, company culture, and safety. A key component of our lean process is interviewing teams to determine the actual ways of working as opposed to what their policies and procedures spell out.

Benchmarking against best practices and proposing improvements that include different levels of Industry 4.0 adjustments gives your business a competitive edge. These modifications could include fine-tuning the running of API workflows so data syncs across systems; improving processes through robotics automation; and building machine learning tools that look for data patterns and continuously offer recommendations for improvement.

The last thing a business needs is a strategic plan that leads it down a path no longer relevant, especially in the face of modern industry and the emerging sources of value creation. Corporate strategies come and go, sometimes in the blink of an eye. That truism has never been more evident in the extensive disruption brought by the COVID-19 pandemic. It’s also witnessed in disruptive technologies such as AI, robotics and IoT. Every corporate strategic plan should be nimble enough to search for and absorb new information on relevant technologies and continuously improve operations to stay ahead of competition and meet market needs.

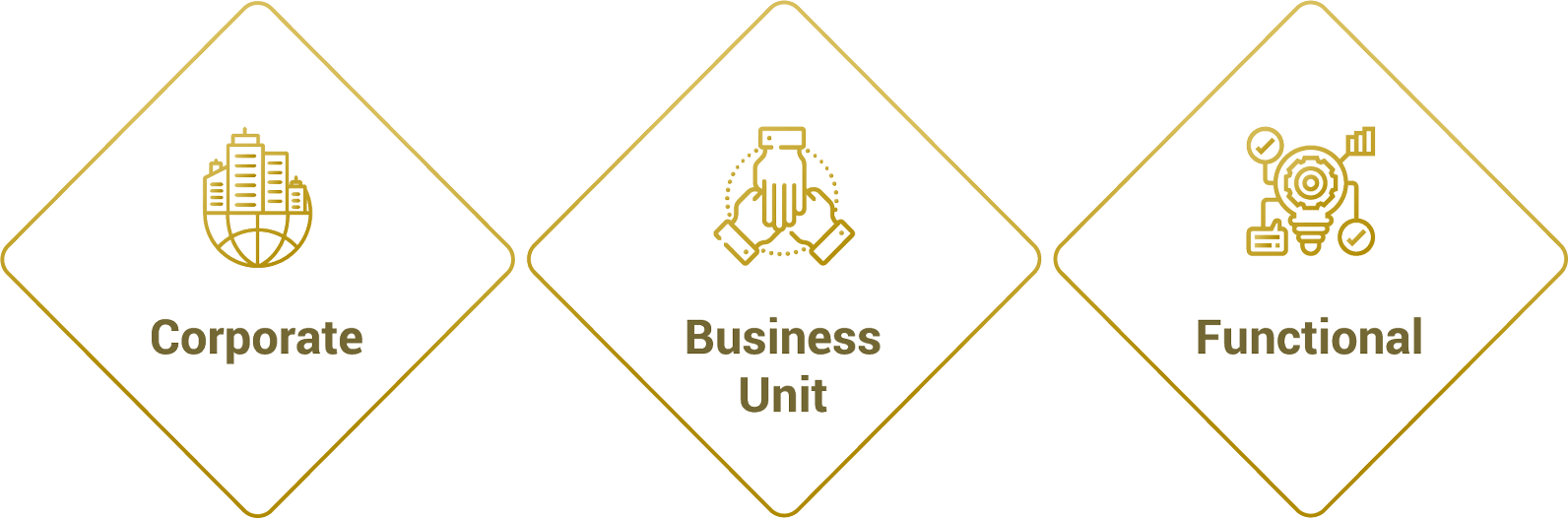

Once our proposals are adopted, we create individual change projects that are designed and timed to move the organization from its current state to its proposed state. In our experience, this requires the alignment of corporate strategy at the business unit and functional levels.

Business level improvements support your organization’s corporate strategic plan as well as each business unit’s strategic plan. If your corporate and business unit level plans are to grow and meet the needs of your markets while your operational plans remain static, it’s unlikely that your organization is going to achieve its objectives.

Functional improvements in organizational shared services and departments receive improvements that directly support their work processes. When any area of business receives strategic or operational updates, the supporting functions must be one of the first areas of the organization to be informed. Operational excellence in functions such as finance, purchasing, inventory, payroll, HR, and IT are often necessary to accelerate critical pathways.

IMPROVEMENT AS A STRATEGIC FUNCTION

We facilitate these adjustments by attaching CI plans to your strategic planning processes and doing the nitty-gritty work essential to carrying your corporate strategy forward. While many strategic planning engagements are often smaller in scope and center on one aspect of strategy, the CI process bores into all levels of the organization to identify the factors that help or hinder the organization’s ability to make improvements.

At the Corporate Strategy Level, our CI processes ensure that divisions and brands can support the operational aspects of the corporate strategy by first assessing competitive and market environments. An example of this is our involvement was to confirm their ability to speed to market with its new EV line of vehicles. Our first step was to ensure each launch-point country assess their logistics to ensure they could support a rapid market entry. In a step-by-step manner, our CI process moved them from their ‘today’ to their ‘future’ structure.

Business Unit-Level Strategy involves working with divisions to reach a point of self-diagnosis and improvement. As example, too many vendors initiating marketing projects with manufacturers can force business units to add more time and cost in support of each venture. Our approach is having your workflow structures planned out to ensure project execution with speed and efficiency. Vendors need to align with the company’s planned workflow and managers given dashboards and KPI’s to know when activities are exceeding budget or time parameters.

Functional Level Strategy becomes more technical as CI begins to require more detail work than that applied to other strategy levels. Functional strategy involves workflow improvements in departments that are shared resources at headquarters and across all business units. Those functional areas would include such areas as finance, purchasing, inventory, payroll, HR, and IT.

Process improvements

Process improvement goes by many names such as business process management (BPM), business process improvement (BPI), business process re-engineering, continual improvement process (CIP), to name a few. Regardless of the nomenclature, they all pursue the same goal: to minimize errors, reduce waste, improve productivity, and streamline efficiency. Our role is to identify, analyze, and recommend improvements of existing business processes to optimize performance, meet best practice standards, or simply improve quality and the customer experience.

REVISITING YOUR SUPPLY CHAIN

The supply chain is the linchpin for organizational excellence and all areas of the organization have a stake in the efficiency and effectiveness of its supply chain. Yours should include CI measures that increase value through integration, harmonization, logistics, and fluctuations in supply flow.

To decrease time and waste, modern six sigma process improvement techniques using best practice mathematical approaches are applied to service, product, or manufacturing workflows to decrease process variability. Some six sigma approaches vary on a scale from fully human processes to fully automated processes, and every combination in between. These improvements are focused on decreasing time and waste, while maximizing productivity and value.

While six sigma is focused on operations-level processes, the techniques used in modern lean six sigma can be applied to all other facets of the business including leadership, capacity building, training, and many other organizational areas.

Agile operations

Agile operations is where modern six sigma and lean form a foundation for improved excellence in processes that repeat over time. Agile borrows from modern IT concepts to introduce deployable tools that teams can use to accelerate efficiency. Best used in medium- to long-term projects or frequent team interfaces that seek to maximize time, agile can deliver higher quality results in shorter intervals.

Similar to lean management, Agile is based on a Kanban structure that becomes more multifaceted depending on the complexities of the project. Projects are broken into phases and each phase has a number of actions that must move forward to complete the phase. Sometimes these projects and workflows are moving simultaneously and at other times, sequentially.

Products + R&D

Product and R&D Improvements is a unique, entrepreneurial level of identifying the factors that help or hinder the organization’s ability to make improvements to market needs. A new world of product improvement systems can create marketplace advantages when product and R&D teams: borrow from the best practices of operations and IT; deliberately seek to incorporate the voices of the customer; and incorporate study to anticipate market demands.

These meaningful product changes result in new benefits to existing customers and enable the organization to reach and serve new markets. While these initiatives are generally thought to pose risks, data show that using improvement structures actually lower risk while increasing value.

Lean management becomes the underpinning of CI when leaders adopt the tenets of continuous improvement and implement them throughout the organization. Teams understand that when projects move uncomfortably fast, improvement is at the end of the tunnel because of the company’s CI orientation. Whether those improvements are investments in current operations or future strategic objectives, when leaders lead with action, teams believe, trust, and are far more likely to buy-in and show commitment.

Operational excellence

Operational Excellence is achieved when continuous improvement creates processes that exceed expectations and 360-degree stakeholder harmony. Operational excellence is more than just charts and visuals, it is the development of a shared belief in the effectiveness of your operations that both supports and accelerates the strategic vision.

We foster and advance internal belief systems that help leaders champion their CI efforts and help managers discover how best to communicate those efforts. We also formulate incentive structures to support CI initiatives such as encouraging the submission of questions and ideas from all corners of the organization and implementing various tools used to guide and sustain organizational behavior change.

Let’s Discuss.

Our consultants are happy to lend ideas and approaches to support your decision making. Contact us today for a quick strategy session.

Want to hear more from us?

Receive ideas, innovative business approaches, and new study information directly to your inbox.